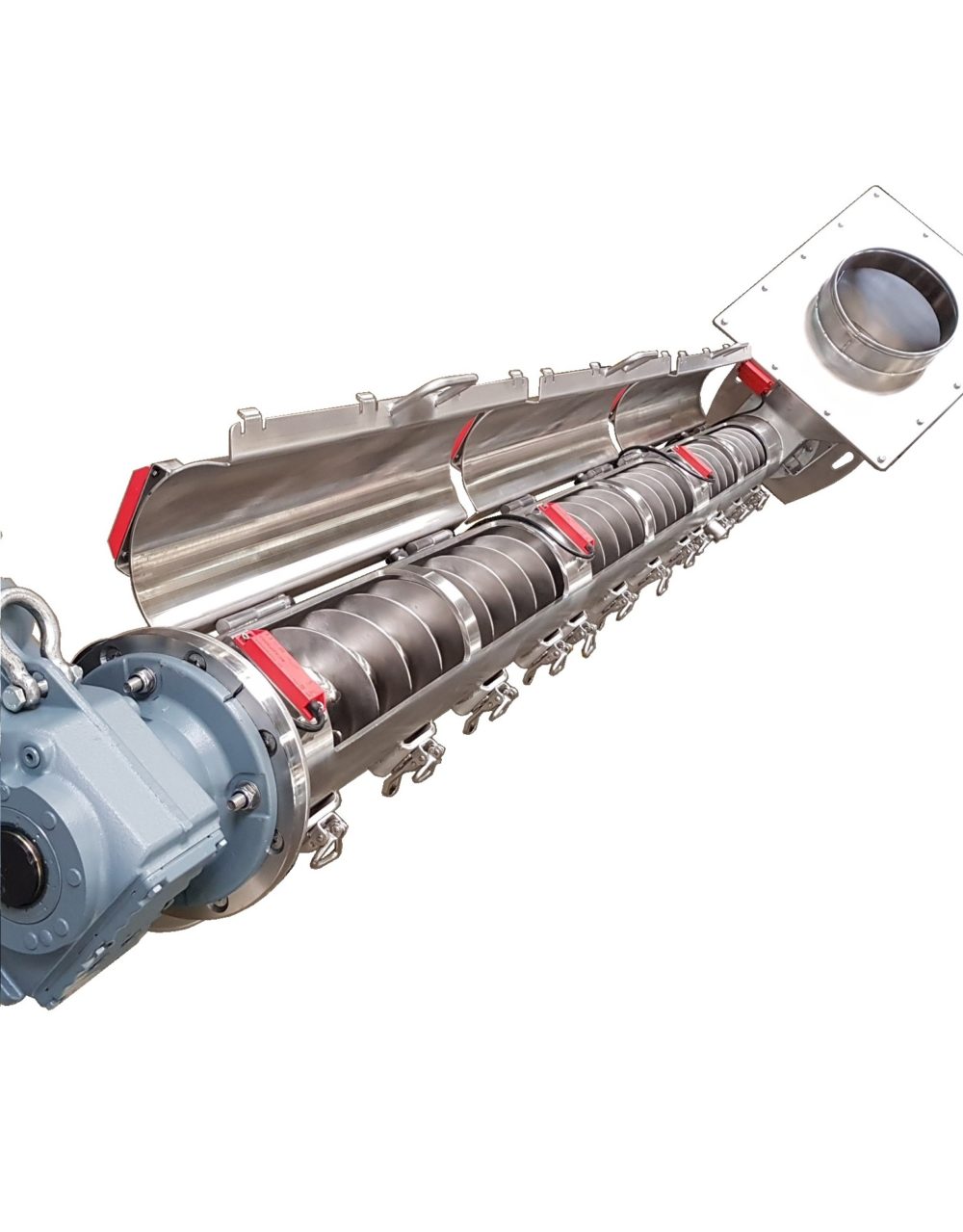

Screw conveyors

The Archimedes screw conveyor is the most commonly used equipment for handling bulk products in a wide variety of industries: agri-food, sugar, chemical, pharmaceutical, wood, paper, cardboard, mineral products, cement, plaster, quarries, waste treatment, sludge, etc..

Archimedes screw conveyors, consisting of a tubular or trough- shaped casing, can be equipped, according to requirements, with solid, ribbon, vane or coreless rotors.

Calculation software allows us to define the main elements of the conveyor reliably and quickly.

Bucket elevators

With either a single or double sheath, belt- or chain-fitted, the bucket elevator can lift bulk solids to heights of up to 50 metres.

Bucket elevators are used for the transport of bulk products, as well as products in dust or granular form or in small pieces. Corneloup offers you custom- made elevators, with a wide choice of materials for sheaths, buckets and straps, which allows them to fit into a large number of industrial installations.

Conveyor belts

100% adaptable transport (length, width, load, flow, curved or straight).

Conveyor belts are designed for handling bulk materials or conveying single loads. They consist essentially of an endless belt of flexible material driven and supported by motorised pulleys. The path of the conveyor belt can be horizontal, ascending or descending, but also straight or curved. Thanks to its many options, especially in terms of belt quality (smooth belt, chevron belt, edge belt), conveyor belts can be used in many applications.

Chain conveyors

Based on the principle of one or more chains driven in a sealed box by one or more drive assemblies via drive shaft couplings, using chain conveyors is essential in certain sectors of activity to meet the needs of conveying over long distances and at variable speeds.

The main technical characteristics are as follows:

- Multiple product inlets and outlets are possible

- Equipped with one or more chains depending on the complexity of the product transfer

- Complete emptying and self-cleaning of the unit

- Low motor power (low energy consumption)

- Low chain feed speed and high flow rate

- Long transport length